Harsh Thakkar

Pandit Deendayal Petroleum University, India

Title: Experimental investigations of ECD process parameters

Biography

Biography: Harsh Thakkar

Abstract

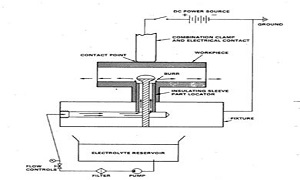

Statement of the Problem: A rapid increment in demand of highly accurate, repeatable finishing process for high value added applications, like aerospace and automotive, has led to the development of technologies like electrochemical deburring (ECD). Thus, it is of utmost importance to evaluate and optimize the performance of ECD process. This study is focused on evaluation of ECD process by comparison of material removal rates and maximum current obtained by variation in process parameters like machining time, electrolyte concentration.

Methodology & Theoretical Orientation: The paper mainly aims to evaluate the performance of electrochemical deburring process by varying certain process parameters during the deburring of internal holes. These parameters include the cycle time, electrolyte type, electrolyte concentrations. The results are obtained by a comparative study of several experimentations and characterization of the deburred area.

Conclusion & Significance: The analysis of ECD process helps to obtain the optimum value of parameters that is essential to increase the productivity of industries that require deburring of components. Deburring of internal geometries can be done by various processes like hand deburring, honing, abrasive jet machining etc. but all these processes do not ascertain specific spatial control over the deburred area, which is possible with electrochemical deburring. Hence, it is important to evaluate the performance of ECD and also to check the economic viability of the process.